The DOE Molten Salt Reactor (MSR) Program serves as the hub for addressing the technology challenges to MSRs to enter the commercial market.

MISSION: Develop the technological foundations to enable MSRs for safe and economical operations while maintaining a high level of proliferation resistance.

1) MSRs can provide a substantial portion of the energy needed for the US to achieve net zero carbon emissions by 2050 and

2) There is a need for an abundant energy worldwide for the foreseeable future.

Determination of the Thermophysical and Thermochemical Properties of Molten Salts – Experimentally and Computationally

Developing new technologies to separate radioisotopes of interest to the MSR community

Radionuclide Release Monitoring, Sensors & Instrumentation, Liquid

Salt Test Loop

Development of materials surveillance technology Graphite/Salt Interaction De-risk the transition from 316H to higher performance alloy 709

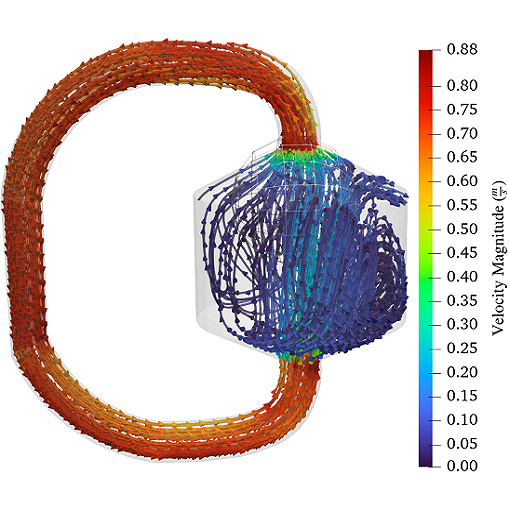

Identify, prioritize, and resolve technical gaps related to mechanistic source term (MST)

modeling and

simulation tools

What are Molten Salt Reactors?

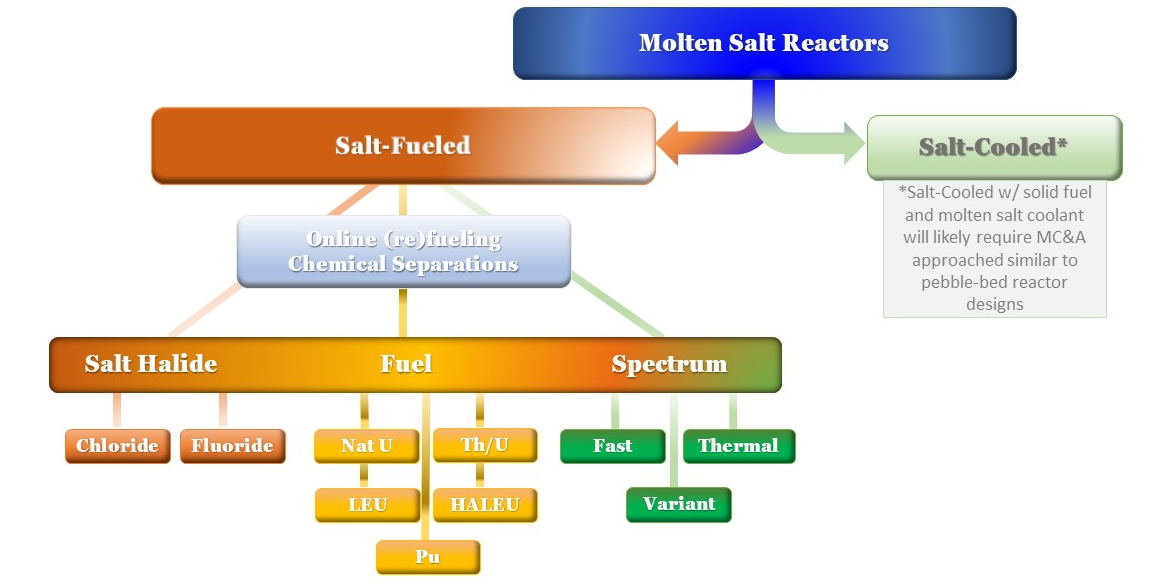

A molten salt reactor (MSR) is any nuclear reactor that employs liquid halide salt to perform a significant function in-core. MSRs include a broad spectrum of design options including:

- liquid- and solid-fueled variants,

- chloride- and fluoride-based fuel salts,

- thermal, fast, time variant, and spatially varying neutron spectra,

- wide range of reactor power scales,

- intensive, minimal, or inherent fuel processing,

- multiple different primary system configurations, and compatibility with

- nearly all fuel cycles.

The breadth of the MSR design space presents a substantial challenge to the completeness and broad applicability of any technology development planning activity. Dozens of design concepts are currently in some state of development, nearly all have been introduced in the past decade, and it is not currently possible to reasonably evaluate which designs will eventually be successful. Nevertheless, MSRs have common characteristics and many technology development issues are broadly applicable to most MSRs

National Technical Director

Patricia Paviet

[email protected]

Office: (509) 372-5983

Cell: (208) 757-2048

Announcements

November 18-20, 2025

Annual MSR Workshop

Knoxville, TN

December 02-05, 2025

4-Day International Training Course on Molten Salt Reactors (MSRs)

Organized by CEA and IAEA

CEA Marcoule Center, France

MSR Awards

Integrated Research Projects (IRP) Funded Projects

NRL Projects Awarded CINR FY22 Funding

- Integrated Effects of Irradiation and Flibe Salt on Fuel Pebble and Structural Graphite Materials for Molten Salt Reactors

CINR Phase II Continuation Awards

- A Molten Salt Community Framework for Predictive Modeling of Critical Characteristics

- Understanding the Interfacial Structure of the Molten Chloride Salts by in-situ Electrocapillarity and Resonant Soft X-ray Scattering (RSoXS)

- Nuclear Material Accountancy During Disposal and Reprocessing of Molten Salt Reactor Fuel Salts

- Optical Basicity Determination of MoltenFluoride Salts and its Influence on Structural Material Corrosion

FY22 SciDAC Award

- Los Alamos National Laboratory to lead study of molten-salt nuclear reactor materials

MSR Annual Campaign Review

MSR Course

Molten Salt Thermal Properties Database (MSTDB)

- University of South Carolina – College of Engineering and Computing — MSTDB

- Oak Ridge National Laboratory — MSTDB

Molten Salt Thermal Properties Working Group

- Sign up HERE

Presentations on Molten Salt Chemistry

Reports

- Chemistry

- Irradiation

- Materials

- Modeling and Simulation

- Off Gas Management

- Safety

GIF Webinars

- Webinar #97 – Jan 2025 – Dr. Jiri Krepel

- Webinar #92 – Aug 2024 – International Panel on MSR

- Webinar #77 – Apr 2023 – Nidia Gallego

- Webinar #73 – Jan 2023 – Jiri Krepel

- Webinar #66 – Jun 2022 – John Vienna and Brian Riley

- Webinar #44 – Aug 2020 – David Holcomb

- Webinar #42 – Jun 2020 – Jiri Krepel

- Webinar #21 – Jun 2018 – Viktor Ignatiev

- Webinar #9 – May 2017 – Elsa Merle