Idaho National Laboratory Change Detection team eyes commercialization

By Paul Menser

With two patents and two R&D 100 awards to its name, Idaho National Laboratory's Change Detection System (CDS) would appear to be a shoo-in for commercialization. Embraced throughout the U.S. government, CDS is diagnostic software that can align two seemingly identical images and enable a person to see even the tiniest variations.

Yet when the INL inventors took a version of CDS tailored toward the nuclear power industry to a commercialization boot camp, their deep dive into "customer discovery" made them readjust their thinking. What they thought would appeal most to potential customers was completely off the mark, but the possibilities their potential customers saw for the program turned out to be much more exciting.

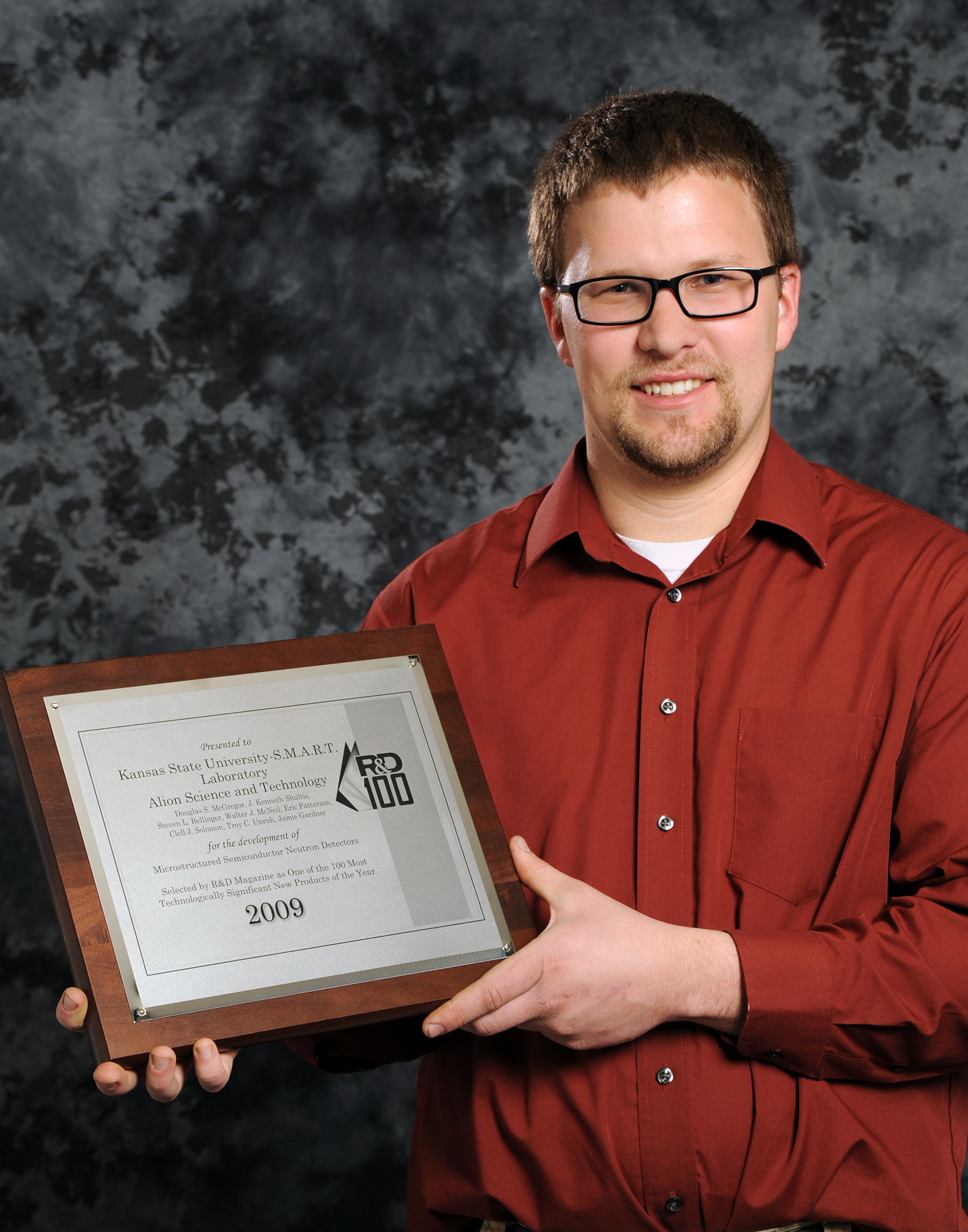

It was all for the better, said Troy Unruh, an INL nuclear engineer and principal investigator of the CDS team that took part in the U.S. Department of Energy's Lab-Corps training program in fall 2016. (The name of the program has since changed to Energy I-Corps.) "It allowed us to understand our customer better and gave us a better sense of what we needed (our product) to do," Unruh said.

It was all for the better, said Troy Unruh, an INL nuclear engineer and principal investigator of the CDS team that took part in the U.S. Department of Energy's Lab-Corps training program in fall 2016. (The name of the program has since changed to Energy I-Corps.) "It allowed us to understand our customer better and gave us a better sense of what we needed (our product) to do," Unruh said.

Programs like Energy I-Corps and DOE's Technology Commercialization Fund are leading examples of how the Gateway for Accelerated Innovation in Nuclear (GAIN) is guiding lab-originated technology to the marketplace. "The objective of GAIN is to accelerate cost-effective commercialization of innovative nuclear energy technologies," said Rita Baranwal, GAIN director.

Before coming to GAIN in 2016, Baranwal was director of Technology Development at Westinghouse, a company with deep roots in the nuclear energy business. Bringing someone with private-sector experience was viewed as critical to GAIN's mission of moving advanced nuclear technologies toward commercialization in extremely competitive energy markets at home and worldwide.

CDS dates back to 2002, when INL's Greg Lancaster and his team were working on image alignment algorithms to highlight minute changes between two or more photos. As aligned images are "flickered" between each other, previously unnoticed differences appear as motion and are easily detected. CDS is capable of batch processing large digital image sets, including X-rays, thermal, light detection and ranging (LIDAR), scanned objects, and digital surveillance cameras. It won its first R&D 100 award in 2003, credited with providing researchers and engineers a tool for seeing subtle discrepancies otherwise impossible to spot by merely comparing pictures side by side. In 2008, it provided the basis for another R&D 100 winner, Antibody Profiling Identification – AbP ID – a tool for testing forensic DNA samples.

Over 15 years, CDS was adopted by dozens of government organizations and widely used in national security-related applications. Eventually, it was suggested the software might be applied to nuclear issues, such as fuel element inspection and hot cell blister formation.

To get more information, the CDS team consulted with researchers, program leads, and workers in Nuclear Science and Technology and nuclear operations at the ATR Complex, the Materials and Fuels Complex, and commercial nuclear power plants. They identified areas that included facility workflow operations, independent remote verifications, work zone inspections in contamination areas, normal versus abnormal status indications, damage analysis (e.g., water hammer and seismic), thermography of live electrical connections, and tracking of fresh boron stains.

The needs assessment led to interest from potential commercialization partners and follow-on funding from DOE. The DOE Technology Commercialization Fund contributed to develop a nuclear-focused version of CDS called Apollo, which has the potential to be widely distributed outside the national lab system. Reflecting the widespread use of smartphones, one feature of Apollo is the ability to reconcile thermal images taken on handheld smartphones.

Unruh said they thought this would be a home run. But in the six weeks of Lab-Corps, hosted at National Renewable Energy Laboratory in Golden, Colorado, the CDS team learned that nuclear plant operators had little interest in using smartphones to take photos. Visits to the River Bend and Waterford nuclear generating stations in Louisiana revealed that stationary cameras at critical locations throughout a plant were much preferred.

What is Change Detection System?

[Click HERE for youTube video]

"There were certain things they validated," Unruh said. "They found uses and got very excited."

Most critically, Apollo was evaluated on the basis of how useful it would be at preventing shutdowns. "To stay competitive, we have to be more efficient," Unruh said. "To shut down a nuclear power plant costs an operator $1 million a day. Any program that would allow them to avoid shutting down and help (operators) make informed decisions would be extremely valuable."

Unruh's team – Lancaster was the entrepreneurial lead and Sontra Yim, a director at the worldwide engineering consulting firm LPI, served as industry mentor – also learned that the most likely Apollo users would not be the plant operators, but rather, consulting companies hired by utilities to monitor their nuclear facilities. Deployment of CDS using the software as a service business model would rely significantly on INL's industrial partnership with New York-based LPI, and the feedback it can provide on measured benefits and cost or time savings.

"These programs are building commercialization into the DNA of our researchers, which leads to industry-relevant research from initiation," said Tammie Borders, INL's point person on Business Development for Industrial Partnerships.

With Energy I-Corps training and its partnership with LPI in hand, the CDS team has put in for another round of DOE Tech Commercialization funding. The money would be used for demonstrating the technology and visiting more plants. The latter is the most valuable use of time, Unruh said. "We found a lot of good applications for change detection at the plants we visited," he said.

The project managers are also keen to tell how CDS fits in with the DOE Office of Nuclear Energy's Nuclear Energy Enabling Technologies (NEET) program objectives to develop cross-cutting technologies that focus on improving performance, and with the Nuclear Energy Institute's "Delivering the Nuclear Promise" initiative. LPI provides consultation services to several nuclear power plants and will incorporate the CDS technology into analysis activities for prognostic maintenance. LPI will be responsible for capturing new imagery at nuclear power plants and interfacing with appropriate system and component engineers to assure the deployment strategy is successful.

INL and LPI have successful working relationships through several Light Water Reactor Sustainability projects to improve nuclear fleet efficiency. This commercialization project will extend the relationship to new researchers in National and Homeland Security and Nuclear Science and Technology.

Printable Version

Printable Version